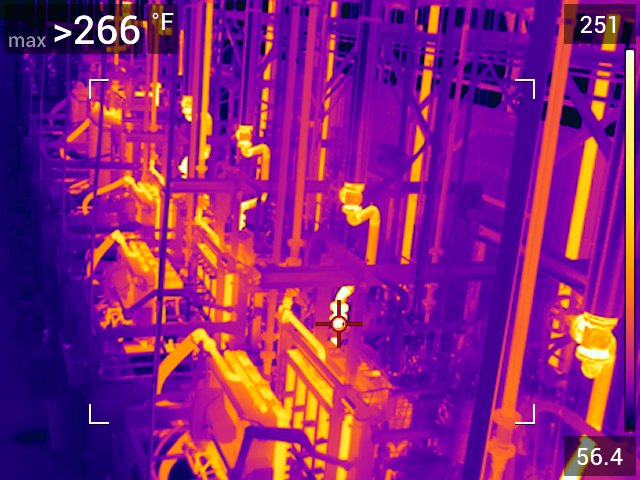

Thermal imaging cameras help to detect issues in advance by identifying abnormal heat patterns, hot spots in electronics, and prevent maintenance issues. This is a part of our EHS safety procedures and annual preventive maintenance routine.

This process is mainly used for monitoring and inspecting equipment and processes. It helps us with identifying hotspots, which can indicate potential issues like overheating components, electrical faults, or mechanical failures. By detecting these problems early, our plants can perform maintenance before any breakdown occurs which greatly aids in reducing downtime and improves our overall efficiency.

Thermal imaging is also used for quality control to ensure products are manufactured within required temperature ranges, ensuring consistency and reliability.

Here are some of the reasons behind using thermal imagining: