Temperature Solutions

EFP’s Temperature Solutions Group offers a wide range of cold chain solutions including the customizable PharmaTuff line, off-the-shelf prequalified eQUAL line, our newest Controlled Room Temperature line, Climatemp, and an environmentally conscious, temperature assurance packaging line, NatureKool.

Our Capabilities

Here at EFP, we pride ourselves on having a full design testing certified lab ran by a team of experienced scientists and engineers. The EFP Center of Excellence Lab completed the International Safe Transit Association (ISTA) Lab Certification in 2019 and continues with recertification every other year. Being ISTA Certified ensures confidence in the success of qualifying specific packaging tests to meet your needs and provides a third-party testing of your existing product along with a standard 20 data package and report. Furthermore, our lab is ISO: 17025 Certified ensuring reliable quality management of your product(s).

EFP has trained Thermal Packaging Engineers and Business Development Managers that assist in the development of a strong cold chain program.

We specialize in reviewing your supply chain at the packing center and throughout the distribution network. This guarantees the proper cold chain packaging design for your product, ensuring zero temperature excursions during your products transit.

EFP has access to a wide network of partners in the cold chain industry and can find you solutions such as data logging and specialized refrigerants. We will help you analyze the lane data throughout your shipping network and design the most efficient packaging solutions for your specific routes.

We work with you to make sure shipping operations are kept within the guidance of United States Pharmacopeia (USP), Utilization Review Accreditation Commission (URAC), Code of Federal Regulations (CFR), and other governing bodies.

The design process for a cold chain shipment is the first step to ensuring your packages arrive safe and within your temperature specifications. The Center of Excellence Lab designs qualified shippers to meet the transit needs of your product(s). Our research into thermal properties, heat transfer, and computer modelling of packaging profiles, combined with experience in the shipping industry, allow us to create a successful solution at an expedited rate.

The design process is centered around your product with a focus on safe transit both physically and thermally. Cold chain shipper designs start with thermal modelling performed by our Packaging Design Engineers. This brings awareness to potential hot spots for your package as well as giving the best configuration for optimized shipping. The computer modeling process also eliminates the “trial-and-error” portion of design which will greatly expedite the qualification of your shipper.

After a passing configuration is found for your desired temperature range, thermal testing will be used to confirm the simulation. Thermal chambers are used to test a pack out of your product that will simulate industry standard profiles such as ISTA 7D or your own custom profile that matches your shipping lanes. Thermocouples within the chamber and your shipper will monitor for any temperature deviations that may occur during the transit providing the compliance team with proof that your shipment stayed at a desired temperature throughout transit.

The design process ends with the client receiving a full lab report with their passing results. Clients can proceed with drop testing to see how durable the packaging is physically and real time in transit monitoring with data loggers that will confirm shipments are staying within their temperature range during an actual transit, known as Performance Qualification.

Qualification is a crucial step in the cold chain packaging process. Proper testing of your product is a guarantee that they arrive to their destination within the desired temperature range. Pharmaceuticals and food can melt, freeze, or become too hot during transit if not properly tested in a specific product environment beforehand. This can go unnoticed if your product has returned to its desired temperature range by the end of its journey. The result can be food that has spoiled or drugs that are no longer effective or sometimes dangerous due to unforeseen changes during transportation.

The Qualification process performed by the Center of Excellence can solve this problem before it occurs. Cold chain qualification is typically associated with pharmaceutical shipping systems, but this compliance standard is also used in life sciences, biological specimens, blood, fresh produce, meats, fish, poultry, adhesives, and other temperature sensitive materials.

Our design, quality, and manufacturing teams produce thermal shippers that stand up to ISTA (International Safe Transit Association) temperature testing. Most sizes have already been tested against ISTA 7D, 7E, and 3A standards for small parcel shipping and provide durable product protection.

The EFP Center of Excellence Lab has the testing capabilities to ensure that your packaging performs to your standards and that solutions are quickly found if problems are discovered either in lab or in the field. The current testing provided by the COE Lab follow ASTM and ISTA methods with the option of custom methods available if required. We utilize thermal chamber testing, insulation testing, compression testing, and drop testing to ensure your product(s) is well-equipped to withstand extreme cold or hot temperatures.

Our Products

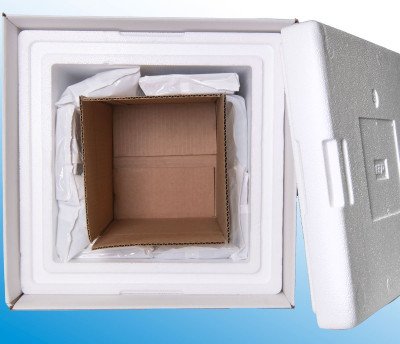

EFP specializes in a simple cold chain packaging design that works from the inside out; beginning with the payload and working out through the refrigerant, insulation, and outer carton to provide a cost effective first article.

EFP’s Climatemp® brand is your all exclusive summer AND winter Controlled Room Temperature solutions; passive systems that hold the 20°–25°C temperature range with no deviations.

EFP’s eQUAL® brand offers an off the shelf, pre-qualified system for your refrigerated shipping needs. These shipping containers have been tested with a minimum and maximum simulated payload volume, providing the payload box with as much product as the customer would like while still staying within temperature specifications. These shippers have been qualified using the ISTA 7E profile for Winter and Summer transits at an economical price.

EFP Gel Packs are a durable, eco-friendly refrigerant for cold chain shipping. The Gel Packs are offered in a variety of standard weights and sizes with custom options available. Every gel that comes off the production line is monitored by an automatic checkweigher to ensure gel is filled with the correct amount of liquid that guarantees the proper performance during transit.

Creating sustainable shipping solutions is at the heart of what we do. EFP is committed to environmental stewardship through innovation. We offer affordable, sustainable, thermally effective shipping solutions nationwide.

EFP developed the Pharmatuff® line of molded EPS shippers to be a pre-qualified cold chain packaging system for high volume users. The Pharmatuff® kits are simple and economical with the pedigree to satisfy your compliance needs.

Industries Served

Our team of cold chain experts target trends across industries to provide durable, versatile, and protective packaging solutions to serve you. Our quality materials are high-grade and can effectively keep your products safe during transit until they meet their destination. We custom mold and fabricate our materials into what you need that guarantees damage-free delivery.

Pharmaceutical

Medical Devices

Food

Clinical Trials

Nationwide Coverage

Get in Touch

Whether you’d like to get to know more about EFP, learn more about our career opportunities or if you’d like to potentially do business, we’d love to talk with you.