EFP is committed to improving the recycling of EPS and other plastics. In this blog, we’ll discuss the status of the plastics recycling ecosystem in the US, the various methods available to recycle plastics, and some of the initiatives being taken by EFP to enhance the recycling of EPS.

Let’s start with a review of plastics recycling in general.

Methods of Plastics Recycling:

There are several methods available to recycle plastics, each with its own processes and technologies. The key methods are:

1. Mechanical Recycling

This is the most common method, where plastics are physically processed to be reused in new products. The steps involved are:

2. Chemical Recycling

Chemical recycling involves breaking down plastics into their basic chemical components using heat or chemicals. These components can be reused to make new plastics. Types of chemical recycling include:

3. Energy Recovery

Energy recovery uses waste plastics as a source of fuel, either by combustion or through processes like pyrolysis. The heat generated can be converted into electricity or used for industrial purposes.

4. Biological Recycling (Biodegradation)

Biological recycling focuses on breaking down plastics using natural microorganisms or enzymes. This method is still largely experimental and limited to specific types of biodegradable plastics.

5. Advanced Recycling Technologies

Innovative approaches such as solvent-based recycling and enzyme-based recycling are emerging, aiming to improve the efficiency of recycling by breaking down plastics into monomers for high-quality reuse.

Current Status of Plastic Recycling Overall:

The state of plastic recycling varies by region across the US, but overall recycling rates today are relatively low. According to estimates, while EPS, PET and HDPE are recycled at rates around 30%, only about 9% of overall plastics waste produced in the US is recycled. The major challenges facing plastic recycling include:

Current Status of Recycling for EPS Transport Packaging:

Although the recycling of EPS has some unique challenges, the recycling of EPS transport packaging (our main focus at EFP) is proving to be very straightforward and very circular.

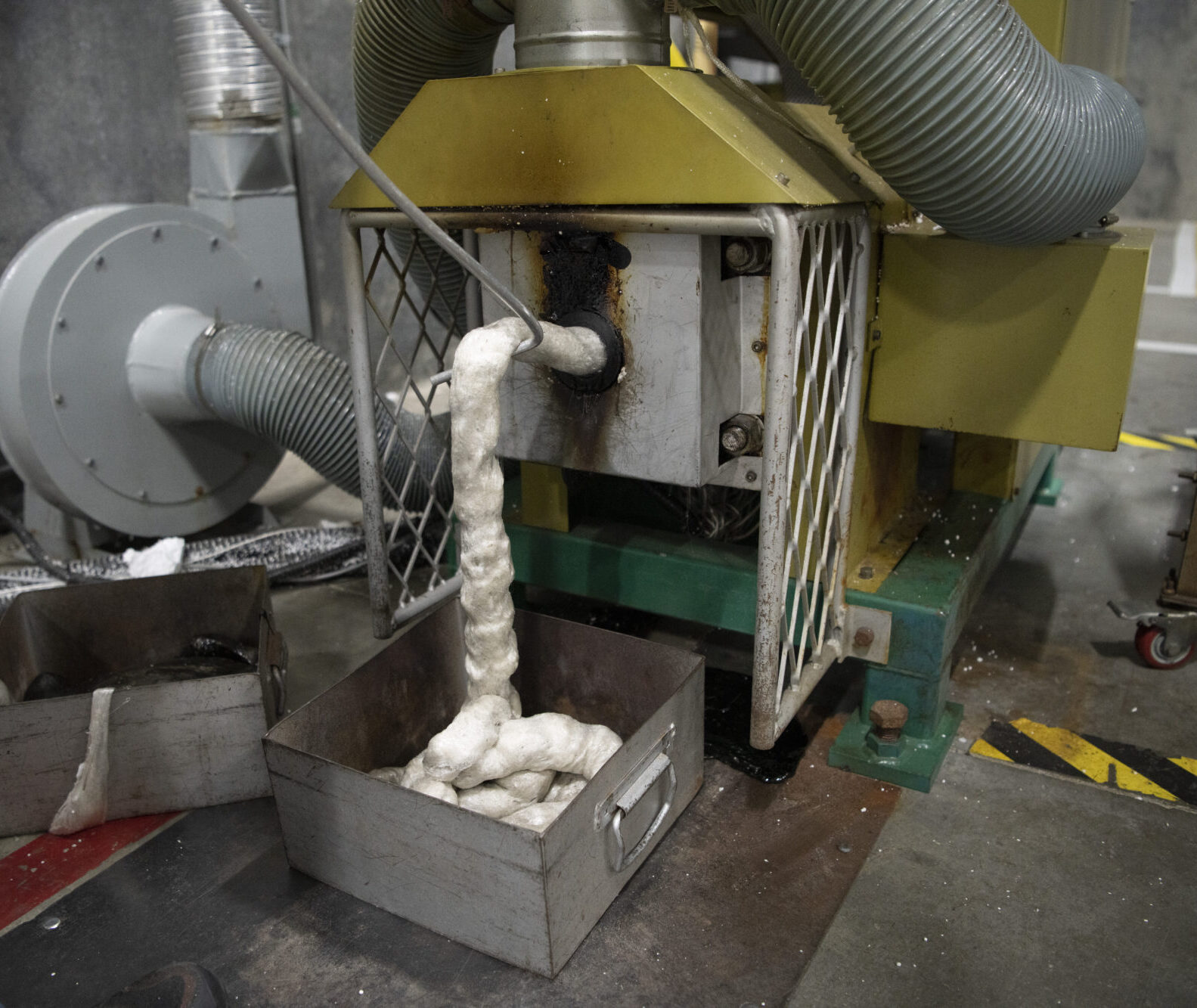

In the case of EPS for transport packaging, the situation is very different. For example, EPS used for protection of appliances during transportation is routinely collected by many Big-Box-Stores. After delivery of an appliance to the consumer, packaging materials used to protect these appliances are returned to the distribution warehouse and sorted. EPS from these facilities is compressed into logs of densified EPS, palletized, and sold back to manufacturers of recycled EPS resins such as Epsilyte.

Impact of Plastic Recycling:

The potential benefits of improving plastic recycling are significant, both environmentally and economically:

Conclusion

Plastic recycling offers substantial environmental, economic, and sustainability benefits. Although the recycling of some plastics is limited by technological challenges, economic factors, and infrastructure gaps, EPS used for transportation packaging is proving to be very circular with an increasingly mature recycling and reuse infrastructure.

Advancements in technology, increased awareness, and governmental policies aimed at reducing plastic waste are driving improvements across the plastics recycling ecosystem. At EFP and in the overall EPS Industry, real progress is being made toward a more sustainable, circular reality. Minimizing the negative impact of plastic packaging on the environment, however, will take the commitment and involvement of numerous stakeholder groups.

We at EFP look forward to working with all interested stakeholders to make the promise of circular use of EPS protective packaging and cold chain packaging a reality!

Written by Joe Grzyb, Director of Sustainability.

Joe Grzyb (pronounced “Gribb”) has over 25 years of experience in leading, managing, and growing high-tech companies primarily in the temperature-controlled packaging industry. Joe was a Co-Founder of NatureKool® and he now joins EFP as our first-ever Director of Sustainability. Before joining EFP, Joe held positions such as Founder of Aspen Technologies, CEO of Phase Change Energy Solutions, and leadership roles at AmeriTech Exports, ITT Defense and the US Air Force.

Keep up with all the latest EFP News!