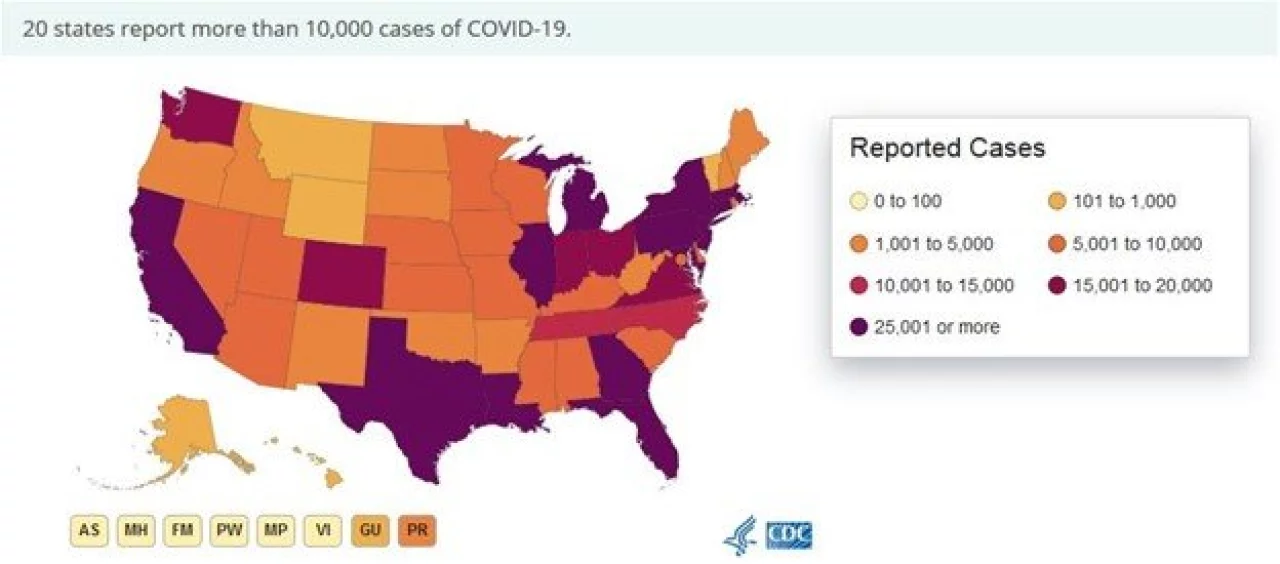

Over the past few months COVID-19 has upended economies and affected everyone’s way of life. The virus is highly contagious and has halted travel, production, and business worldwide. One only needs to turn on the nightly news to see the effects that the Coronavirus is having on people’s lives both physically and emotionally. A global effort is taking place to rapidly develop a vaccine for the virus with faster test kits. When a vaccine is approved for use to combat the virus, it will be essential that the cold chain supply network is prepared to distribute worldwide to return some normalcy to our everyday lives.

A “pre-qualified” cold chain packaging solution is the fastest route with the least amount of risk to get a vaccine to a patient. With a cold chain packaging solution, you receive an uninterrupted series of refrigerated distribution activities that ensure the vaccine will get to the patient at its desired temperature. A pre-qualified system has already been tested using thermal testing chambers against the industry standard ambient profiles to ensure reliable, compliant protection in both summer and winter months.

Another factor to be considered when creating a pre-qualified system is the minimum and maximum amount of items that can be safely shipped in that particular packaging system. In the case of a Corona Virus vaccine, the maximum payload will be the most important factor initially since the vaccine would be sent in large quantities to hospitals and health departments first with shipments of single quantity vaccines sent to doctor’s offices in the weeks and months to follow. Many cold chain shipping solutions exist today that are pre-qualified which can safely ship a COVID-19 vaccine in large quantities that mitigate risk of the vaccine experiencing temperature excursions. Following the initial launch, the next step would be to drive the cost of shipping down by creating unique and more economical cold chain solutions.

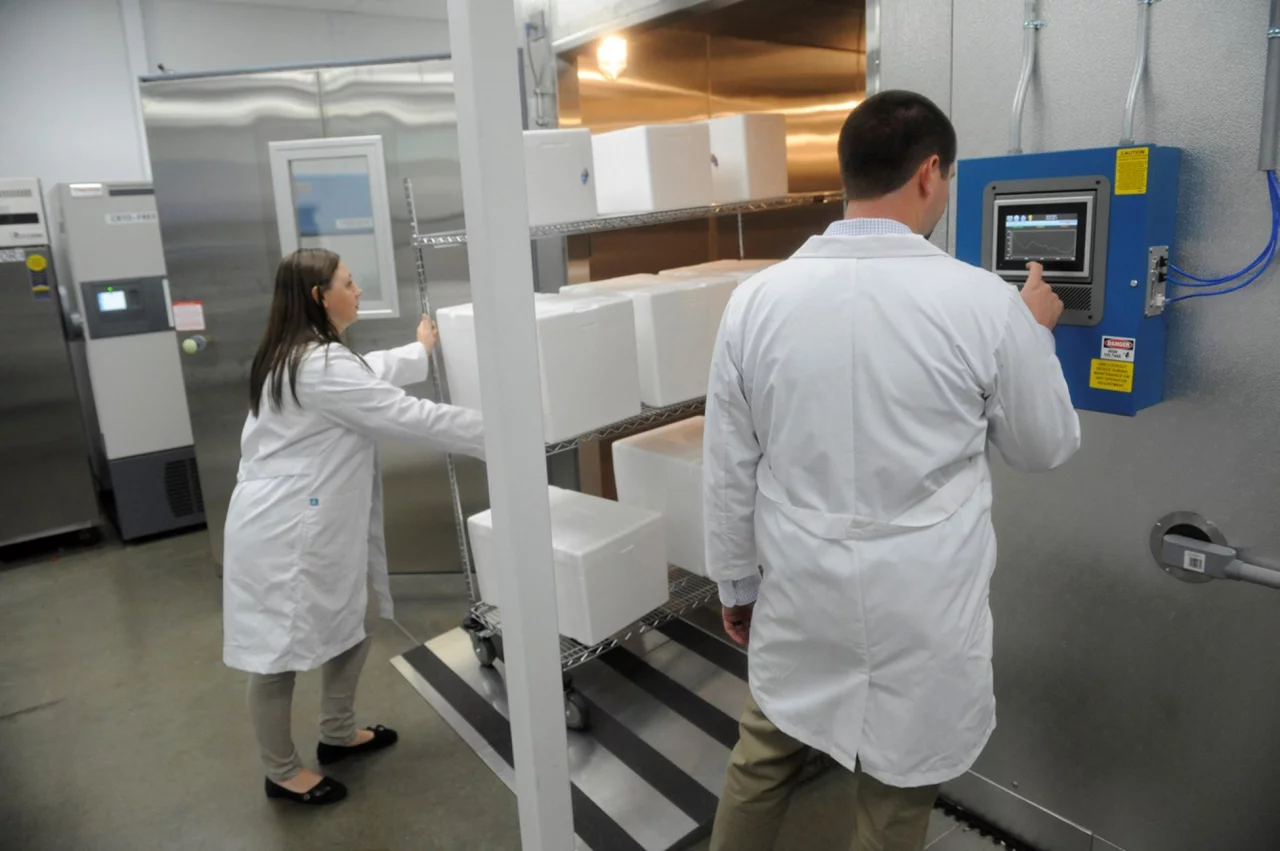

After the COVID-19 vaccine is developed, cold chain suppliers will have access to the information they need to develop a more “fine-tuned” solution for shipping the vaccine. This information includes the safe temperature range the packaging must hold in transit, the dimensions of the vaccine’s container, and the volume of the liquid in the primary package. Allowable excursions will most likely not be available initially since there will have been little time to perform stability studies. The rapid development of a unique shipping solution for the vaccine can begin once this information is obtained. Simulation software can be utilized in tandem with design qualification testing to quickly find an insulated shipping container and a pack out configuration that best-fits the amount of vaccines that will be shipped for each location within a 1-3 week time period. Operational Qualification (O.Q.) and Performance Qualification (P.Q.) can then be performed to ensure the design will successfully transport a COVID-19 vaccine with zero degradation of efficacy.

EFP, LLC. and the COE Laboratory have experience with rapid development of cold chain shipping solutions. We successfully help clients who need to launch a cold chain product on an accelerated schedule. The initial use of pre-qualified solutions in the interim while a more cost effective solution is rapidly developed has been a key factor in this success. The same formula would allow for the COVID-19 vaccine to be rapidly distributed worldwide once it is developed.

Whether you'd like to get to know more about EFP, learn more about our career opportunities or if you'd like to potentially do business, we'd love to talk with you.