Protective Packaging

Offering both highly customized contract manufacturing as well as turnkey products, our in-depth design expertise allows us to develop creative solutions to solve our customer’s most complex problems.

EFP offers you a variety of quality materials to fit your needs. Each of our materials are high-grade and can effectively keep your products safe during transit.

Our Capabilities

At EFP, we customize your packaging needs to safely ship your products to their final destinations. Whether it be a special type of packaging, or you are in need of certain insulating properties, we can help you with our multiple capabilities.

EFP has a full design staff in multiple locations to help bring your specific project needs to life. Our design and testing process includes drop testing and CNC samples/prototype capabilities to guarantee our molds fit the specified criteria that your projects require. Our drop testing is used to verify that the structural integrity of our designs withholds the shipping and distribution of your products.

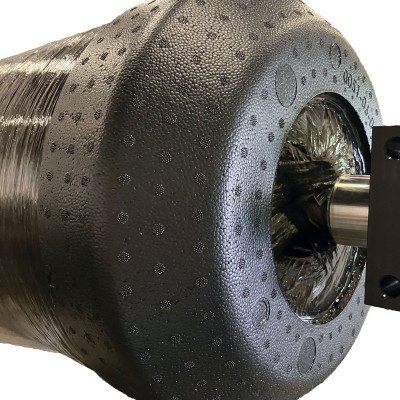

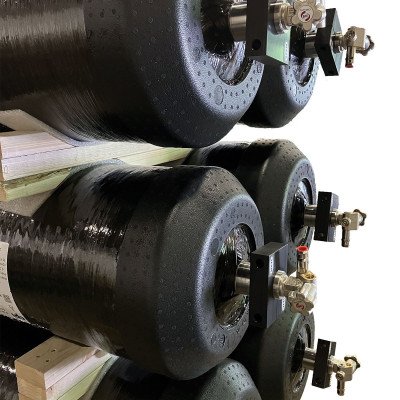

EFP customizes molded shapes for your specific packaging needs. Our ability to mold precision parts with our access to multiple presses and press sizes ensures that we are able to serve varying project types. We can mold anything from cups to protective packaging to insulation for RVs, you name it.

We have a large variety of machinery that aids in fabrication here at EFP. These machines allow us to produce unique solutions using multiple materials and manufacturing processes. With our access to slicers, down cutters, profile cutters, skivers, and gluing operations at our locations nationwide, we can serve you and your projects with ease.

At EFP, we make a commitment to carrying inventory, offering Vendor Managed Inventory (VMI), and to developing Kanban workflow management.

VMI is a proven inventory model designed to streamline inventory management and order fulfillment. The benefit of this service is that it includes faster inventory turns and higher in-stock percentages for when your company needs more product. Kanban allows us to effectively help your company by producing product by customer demand which helps minimize waste activities without sacrificing productivity.

EFP also partners with logistic services so that you don’t have to worry about how your product will get to you after the manufacturing process is complete. Our logistic services ensure that your products get to you in a safe and timely manner.

As part of the EFP manufacturing process, we assemble your products for shipment. The benefits of our assembly process include better lead times, lowered overhead costs, and reduced fulfillment and shipping mistakes. The assembly of your items enables us to mass produce your products quickly and more efficiently.

Our Materials

Durable, versatile, and protective, our quality materials are high grade and can effectively keep your products safe during transit until they meet their destination. We custom mold and fabricate our materials into what you need that guarantees damage-free delivery.

EPS is a rigid plastic that was originally developed for general packaging applications and food containers. There are multiple advantages to EPS, some including it is recyclable, has excellent insulation properties, is a natural choice for strength, protection, price, and versatility, and that it is safe for food contact as it does not support bacterial growth and is resistant to moisture. EPS is also proven to produce minimal waste and reduce the carbon footprint.

EPP is a rigid closed cell foam that has superior cushioning abilities. It is a cost-effective choice for heavy parts as it has great energy absorption, is 100% recyclable, and has a high strength to weight ratio.

EFP has various other materials that we use for fabrication, including DOW Styrofoam (blueboard) and Expanded Polyethylene (EPE). DOW Styrofoam is an extruded polystyrene that encompasses great insulation properties due to having a R-value of 5 per inch. Expanded Polyethylene has great cushioning properties as it recoils after impact. EPE is a more economical option than Expanded Polypropylene (EPP) for not as heavy products where multiple drops/impacts are expected.

Industries Served

Our team of packaging experts target trends across industries to provide durable, versatile, and protective packaging solutions to serve you. Our quality materials are high-grade and can effectively keep your products safe during transit until they meet their destination. We custom mold and fabricate our materials into what you need that guarantees damage-free delivery.

Appliances

Kitchen & Bath

Furniture

HVAC

RV

Other

Nationwide Coverage

Get in Touch

Whether you’d like to get to know more about EFP, learn more about our career opportunities or if you’d like to potentially do business, we’d love to talk with you.