Shipping a product at a constant temperature continues to be a growing trend in both the medical and food industry. While a refrigerator or freezer truck can provide an active system to keep products at their desired temperature, this option is impractical and costly for Last Mile logistics. Most end users of cold chain shipments are either medical professionals who need medicine or shots to their office, patients that need pharmaceuticals directly to their door, or meal kit customers. Providing a refrigerator truck (reefer truck) to each of these locations separately will quickly add up in cost and will provide zero protection once a delivery is left at someone’s doorstep. A passive system solves this last mile problem by using phase change materials to protect the shipment from thermal extremities while it is in transit or sitting at the end user’s home.

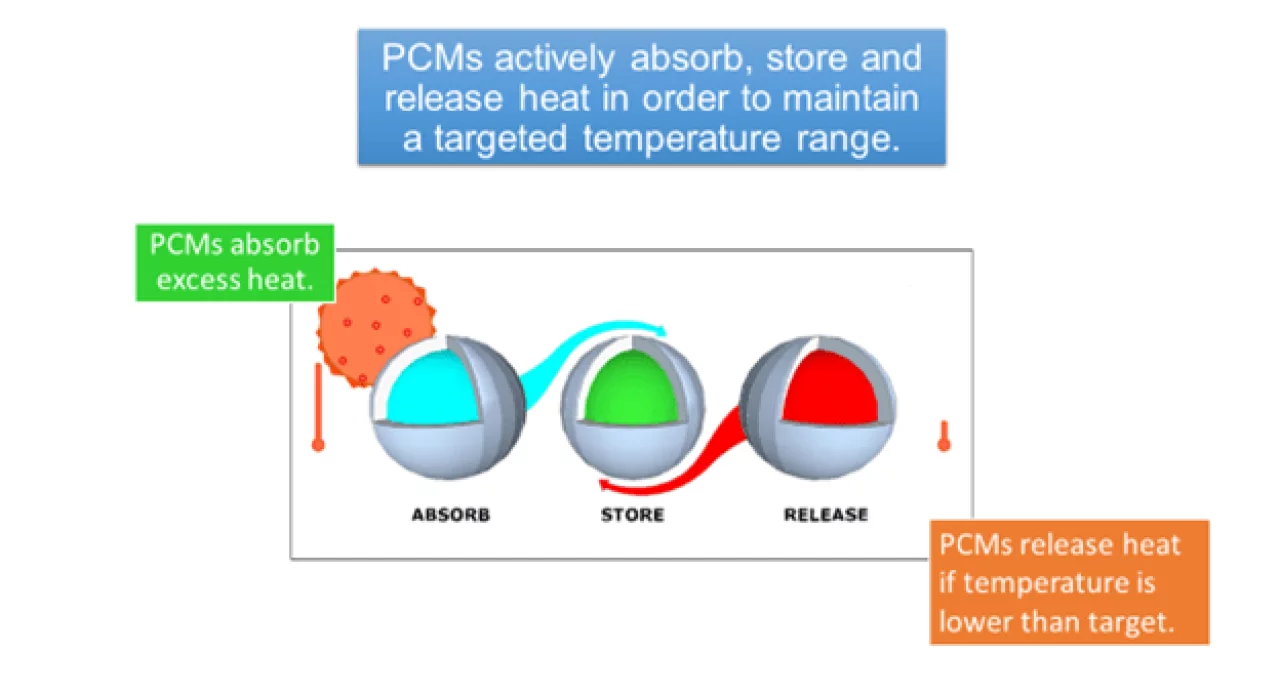

A Phase Change Material (PCM) is a substance used in Cold Chain shipments to assist in keeping a parcel in a desired temperature range. The thermodynamic properties of the phase change material provide protection by absorbing energy during melting, releasing energy during solidification, or providing more mass to a payload to prevent thermal shock. Three of the most commonly used phase change materials today are water-based Gel Packs, Controlled Room Temperature Packs, and Dry Ice. There are many popular uses for each of these as well as the hurdles that come with them.

Water-based gel packs are the most popular PCM used in the cold chain industry today and are generally utilized in 2°C – 8°C packages as well as short-term frozen packages. Gel packs rely on water’s high heat capacity and heat of fusion values to guard against the energy transfer that would otherwise go into the payload of a shipper. Gel packs also provide the same ability as regular ice for shipping frozen products but with the advantage of no leftover water as the ice melts. Gel packs are the most economical of the phase change materials and have the green characteristics of being biodegradable, recyclable, and reusable.

Controlled Room Temperature (CRT) materials are used to keep their shipments close to room temperature during their transit, commonly in the 20°C – 25°C range. CRT materials are less thermodynamically efficient as gel packs and will generally require more volume of the CRT to obtain the same transit times as gel packs would provide. The cost of CRT materials are the highest of any phase change material on the market currently but are reusable and easy to condition as long as the pack out location has air conditioning.

Dry Ice is the frozen form of Carbon Dioxide and is used for frozen shipments with long transit times. The melting point of dry ice is -78.5°C which ensures your shipment will stay well below the freezing point. The advantage of dry ice is that it will sublimate from a solid directly into a gas leaving no liquid to damage your payload. The main disadvantage of dry ice is the cost. Dry ice is not very economical, can only be used once, adds a large amount of weight to your package, and can come with hazmat penalties from shipping companies.

EFP is actively developing new Phase Change Materials with lower melting points than water to take the place of dry ice. We believe that this will be the most cost efficient and bring valuable opportunities to our new and existing customers. If you need more information on Phase Change Materials or need help with your Last Mile shipments, contact us to schedule a consultation and begin designing your solution.

Whether you'd like to get to know more about EFP, learn more about our career opportunities or if you'd like to potentially do business, we'd love to talk with you.